English

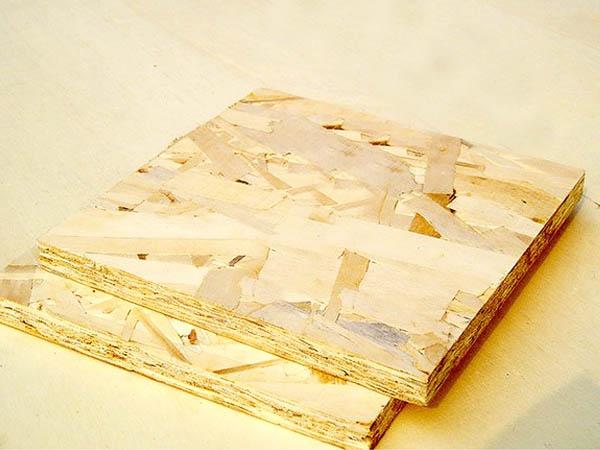

lywood, also known as engineered wood panel, is a remarkable innovation in the wood processing industry. It is made by layering multiple thin sheets of wood (called veneers) in alternating grain directions and bonding them with specialized adhesives under heat and pressure. This cross-grain structure gives plywood superior strength, excellent shape stability, and warp resistance.

Plywood is composed of three main components:

Core: Multiple veneer layers peeled from round logs.

Face/Back Veneers: Thin surface layers selected for aesthetics.

Adhesives: Used to bond the layers together, including:

+ Water-resistant glues: Phenolic, Melamine

+ Moisture-resistant glues (MR): Urea Formaldehyde (UF)

Softwood Plywood: Made from species like Radiata Pine, Poplar.

Hardwood Plywood: From species such as Meranti (Lauan), Canarium, Birch...

Interior Use: Uses UF glue (cost-effective) for furniture and cabinetry.

Exterior Use: Requires higher-grade adhesives like Phenolic or Melamine to ensure water and weather resistance.

Excellent load-bearing capacity

Minimal warping, shrinking, or twisting

Smooth, durable surface with high brightness

Outstanding moisture resistance and dimensional stability

Commercial Plywood: MR glue, for indoor use

Water-Resistant Plywood:

Formwork Plywood: For construction

Moisture-Resistant Plywood: Ideal for kitchen cabinets, doors, humid environments

Marine Plywood: For boats, made with hardwood + waterproof glue

Fancy Plywood: Thin core (<6mm) with decorative veneer (≥0.2mm) for high-end furniture

Standard Commercial Plywood

Structural Plywood

Film-Faced Shuttering Plywood

Natural Veneer-Faced Plywood

Marine Grade Plywood (BS1088 Standard)

Plywood for Container Flooring

Lamin Board / Multiboard

Laminated Veneer Lumber (LVL)

Blockboard / Lumber Core

We source wood from Vietnam, Laos, Cambodia, Myanmar, Africa, and South Africa, including:

Meranti (Philippine Lauan)

Keruing, Kapur, Okoume (Gaboon)

Radiata Pine, Birch, Poplar, Light Mixed Hardwoods

Standards: JPIC, IHPA, BS...

UF (Urea Formaldehyde) – For indoor use (low-cost)

MR (Moisture Resistant) – Moderate moisture protection

Melamine – High durability, good for damp environments

Phenolic (WBP – Waterproof Boiling Proof) – Ideal for marine and shuttering applications

A/B – High visual quality, minimal defects

B/BB – Good face, average back

B/C – One quality face, back suitable for veneer overlay

BB/CC, PBB, Utility, B2, B3 – For structural or underlayer use

Thickness: 2.5mm – 25mm

Width: 1220mm (4 feet)

Length: 2440mm (8 feet)

Contact us today for personalized consultation and quick quotations!